- Introduction

- What is a Frequency Counter?

- Ensure Long-Term Precision with Calibrated Premium Used Equipment

- Frequency Counter Types

- 9 Key Features to Look for in a Frequency Counter

- Frequency Range

- Resolution

- Accuracy and Precision

- Input Sensitivity

- Measurement Speed

- Display and Interface

- Signal Input Type

- Stability

- Portability and Size

- How to Select the Right Frequency Counter for Your Needs

- 6 Tips for Buying a Used Frequency Counter

- 1. Check the Calibration History

- 2. Assess the Condition of Input Channels

- 3. Verify Software Compatibility

- 4. Factor in the Availability of Spare Parts

- 5. Source From a Reputable Reseller

- 6. Compare Warranties and Return Policies

- Common Mistakes to Avoid When Buying a Frequency Counter

- Maintenance and Calibration Best Practices for Frequency Counters

- Measure with Confidence Using the Perfect Frequency Counter

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

此页面暂时不提供中文版本。我们计划在不久的将来提供更多内容并支持中文。

感谢您的投票。You’re troubleshooting a communication systems project and every second counts. You reach for your frequency counter, but it struggles to lock onto the signal or give you an accurate reading.

In fast-paced environments where precision is everything, this can lead to frustrating delays and costly miscalculations.

Engineers often face this challenge when their frequency counter doesn’t align with the specific needs of the application—whether it’s the wrong frequency range, poor resolution, or just an outdated device that isn’t calibrated for modern tasks.

In this guide, we’ll break down what to look for when choosing a frequency counter, how to match the right model to your specific engineering needs, and share six practical tips for buying used equipment. From understanding the different types of frequency counters to assessing key features like resolution and input sensitivity, we’ll help you make an informed decision that ensures long-term precision and performance.

What is a Frequency Counter?

A frequency counter is an electronic instrument used to measure the frequency of an input signal, typically displayed in hertz (Hz). It works by counting the number of cycles or pulses in a signal over a specific time period.

In engineering, frequency counters are essential tools for testing and measuring signals in various fields, particularly in communications, RF (radio frequency), and electronics. They are commonly used to verify signal integrity, test oscillator circuits, and troubleshoot communication systems, ensuring that devices operate within their intended frequency ranges.

Ensure Long-Term Precision with Calibrated Premium Used Equipment

Frequency Counter Types

There are three main types of frequency counters commonly used in engineering: direct, reciprocal, and time-interval frequency counters. Each serves a specific purpose depending on the level of precision and the frequency range being measured.

- Direct frequency counter: A direct frequency counter works by counting the number of signal cycles within a fixed time period. It is straightforward and ideal for simple, high-frequency measurements where extreme precision isn't necessary. These are often used in applications like basic RF testing and communication system maintenance.

- Reciprocal frequency counter: This type of counter improves measurement precision by determining the time it takes for one cycle of a signal to complete, then reciprocating that time to calculate frequency. Reciprocal counters are more suited for tasks requiring higher accuracy, especially for measuring low-frequency signals or signals with a wide dynamic range. This makes them ideal for precision testing in lab environments, especially where small frequency deviations matter.

- Time-interval frequency counter: Time-interval counters measure the time between two specific events, making them perfect for applications like pulse timing and phase-locked loops. This type is often used in radar, satellite communication systems, and timing control applications, where exact intervals between signals are critical.

Choosing the Right Type

- For high-frequency signals (like RF), a direct frequency counter is a cost-effective and practical choice.

- If you're dealing with low-frequency signals or need higher precision, a reciprocal frequency counter is the better option.

- For timing measurements and specialized applications like phase comparisons, a time-interval frequencycounter will deliver the accuracy required.

Keysight offers a range of premium used frequency counters, including high-end models like reciprocal and time-interval counters, at a fraction of the cost. Engineers can access precise, reliable tools without the high price tag of new equipment, making even advanced counters more accessible.

| Type | Accuracy | Speed | Applications |

|---|---|---|---|

| Direct Frequency Counter | Moderate | Fast | Basic RF testing, communication maintenance |

| Reciprocal Frequency Counter | High | Moderate | Precision lab testing, low-frequency measurements |

| Time-Interval Frequency Counter | High | Moderate to Fast | Timing controls, radar, satellite communication |

9 Key Features to Look for in a Frequency Counter

Selecting the right frequency counter for your engineering needs goes beyond simply picking the first model you find. To ensure you’re investing in the right tool, you need to consider a range of key features that impact performance, precision, and usability.

Whether you’re measuring audio frequencies, RF signals, or working with microwave communications, understanding these features will help you make an informed decision. Let’s dive into the nine critical factors you should prioritize when choosing a frequency counter.

Frequency Range

The frequency range of a counter determines what signals it can measure. Different applications require varying ranges, and selecting a counter that supports the frequencies you work with is crucial. For instance, audio engineers may only need a counter with a lower range, while RF engineers require tools that can handle much higher frequencies.

Here’s a breakdown of typical frequency ranges needed for different types of measurements:

- Audio frequencies: 20 Hz to 20 kHz

- Radio frequencies (RF): 3 kHz to 300 GHz

- Microwave signals: Above 1 GHz, typically up to 30 GHz

When selecting a frequency counter, consider the specific signals you’ll be working with. If you're dealing with low-frequency signals like audio or mechanical systems, a counter with a limited range will suffice. However, for applications like RF signal testing or microwave communications, you’ll need a counter with a much higher frequency range to ensure accurate measurements.

For example, an RF engineer working on wireless communication systems might require a counter that covers a range of 100 MHz to 3 GHz, while a technician working on microwave circuits may need a counter that supports up to 20 GHz. Choosing a frequency counter that matches the frequencies you’ll encounter will ensure reliable results in your tests and measurements.

Resolution

Resolution in a frequency counter refers to how small of a difference in frequency it can measure. The higher the resolution, the more precisely you can detect minute variations in frequency. This is particularly important in applications that demand high accuracy, such as communications or aerospace engineering.

For example, a frequency counter with a resolution of 1 Hz can differentiate between a signal at 1,000,000 Hz and one at 1,000,001 Hz, while a counter with 0.1 Hz resolution would detect even smaller changes.

Resolution plays a vital role depending on the frequency range you're measuring:

- Low-frequency signals: Higher resolution is needed to detect smaller changes. For instance, when testing audio signals, you might need a resolution of 0.01 Hz to ensure that even the smallest variations are recorded.

- High-frequency signals: While less resolution is needed here compared to low-frequency signals, having a counter with good resolution helps maintain accuracy, especially when testing RF and microwave systems. In these cases, a resolution of 1 Hz or better is typically sufficient.

Choosing a frequency counter with adequate resolution ensures even the smallest frequency fluctuations are captured, providing you with the level of precision required for your specific application.

Accuracy and Precision

Accuracy and precision are critical when ensuring that your frequency counter provides reliable and consistent results over time. Accuracy refers to how close the measured frequency is to the true value, while precision refers to the consistency of the readings across multiple measurements. Both are essential for engineers who need dependable data.

Several factors affect the accuracy and precision of a frequency counter:

- Internal oscillator quality: A high-quality internal oscillator (such as a temperature-compensated crystal oscillator, or TCXO) can significantly improve a counter’s accuracy.

- Calibration: Regular calibration ensures that the counter continues to perform accurately over time. Uncalibrated counters may drift and produce unreliable results.

- Environmental conditions: Temperature, humidity, and even vibrations can impact the precision of measurements, especially in sensitive applications.

Here’s how accuracy and precision affect various applications:

- Low-frequency applications: In fields like audio engineering, where even minor fluctuations can impact sound quality, high accuracy is critical.

- High-frequency applications: In telecommunications and RF engineering, precision ensures that signals stay within the expected frequency range, preventing interference or data loss.

A high-precision, well-calibrated frequency counter ensures that your measurements are not only correct in the short term but also reliable over the long haul, reducing the need for repeated tests or corrections.

Input Sensitivity

Input sensitivity refers to a frequency counter's ability to detect and accurately measure weaker signals. The higher the input sensitivity, the more effectively it can measure low-amplitude signals, which is critical in fields like telecommunications and RF testing. Sensitivity is especially important when working with weak or low-power signals, where small variations can impact the overall system performance.

Examples of how input sensitivity affects performance:

- Low-power RF signal measurements: In wireless communication systems, a highly sensitive counter can detect weaker signals, ensuring accurate readings even in environments with signal degradation.

- Telecommunications troubleshooting: A counter with high sensitivity is essential for diagnosing issues in systems where signal strength is inconsistent or fluctuating.

- Satellite and radar systems: In applications where signals can travel long distances and lose strength, a sensitive counter ensures reliable measurements.

Choosing a frequency counter with sufficient input sensitivity ensures that even weak signals are captured, improving the overall accuracy of your measurements.

Measurement Speed

Measurement speed determines how quickly a frequency counter can capture and display results. In environments that require high-volume signal testing, such as production lines or field testing, fast measurement speeds are crucial for keeping up with demand.

- High-volume signal testing: Engineers working on production lines need a counter with fast measurement speed to ensure they can test multiple devices without slowing down operations.

- Trade-off between speed and accuracy: While faster counters can process more signals in a shorter time, they may compromise on accuracy. This trade-off is acceptable in scenarios where minor discrepancies won’t affect the overall outcome.

- Recommendation based on application: For environments where precision matters more than speed (e.g., lab work or research), a slower but more accurate frequency counter is preferred. Conversely, for quick diagnostics and high-throughput environments, faster counters are more practical.

Balancing speed and accuracy is key to selecting the right frequency counter for your tasks.

Display and Interface

A clear, intuitive display is essential for quickly reading and interpreting frequency measurements, especially in fast-paced work environments. A well-designed interface can make all the difference in terms of efficiency and ease of use.

- Modern digital interfaces: Many frequency counters now come with digital displays that offer easy-to-read measurements, reducing the chance of errors or misinterpretation.

- Touchscreen functionality: Counters with touchscreen interfaces provide a more user-friendly experience, allowing engineers to adjust settings and switch between modes quickly, without needing to navigate through complicated menus.

- Data integration: Some advanced counters can integrate with external software systems, enabling engineers to export data directly for further analysis or documentation, streamlining the overall workflow.

For engineers working in high-pressure environments, an intuitive display and user-friendly interface can significantly reduce the time spent setting up and interpreting measurements, allowing them to focus on the task at hand.

Signal Input Type

Frequency counters can accept different signal input types, and it’s crucial to ensure the counter you choose supports the signal type most relevant to your application. The two most common input types are analog and digital, each serving different engineering needs.

- Analog input: Used for measuring continuous signals, such as those found in RF testing or audio systems. Analog inputs are essential in applications like communications, where signal quality and waveform shape are critical.

- Use case: RF testing in telecommunications or broadcasting systems, where engineers need to measure frequency, amplitude, and waveform shape from an analog signal.

- Digital input: Primarily used for measuring discrete signals, such as those in telecommunications or computing systems. Digital inputs are common when testing signals that are either on or off, or in systems where pulse counting is required.

- Use case: Telecommunications, where engineers measure digital pulse signals to test the integrity of communication systems.

Choosing the correct signal input type ensures compatibility with your equipment and leads to more accurate measurements. If your work involves both analog and digital signals, consider a counter that supports both types to cover all testing scenarios.

Stability

Long-term stability is vital for ensuring consistent, reliable measurements over time, particularly in precision applications. Stability refers to the ability of a frequency counter to maintain accuracy despite external factors like temperature changes or aging components.

Factors that impact stability:

- Temperature fluctuations: Frequency counters can be sensitive to changes in temperature, which may affect the internal oscillator, causing measurement drift. A stable counter will include temperature compensation to minimize these effects.

- Aging of components: Over time, internal components such as oscillators can degrade, leading to less reliable results. Regular calibration and high-quality components are key to maintaining long-term stability.

Stability is especially critical in applications like aerospace, communications, and research, where even minor deviations in frequency measurements can lead to significant performance issues. Opting for a frequency counter with a high-stability oscillator, like a TCXO or OCXO, ensures that your measurements remain accurate over extended periods.

Portability and Size

When choosing a frequency counter, portability and size should align with your specific use case. The main options are handheld and benchtop models, each offering unique advantages.

- Handheld models: Ideal for field testing or on-the-go applications, handheld frequency counters are compact and lightweight. Their portability makes them perfect for engineers who need to take measurements in different locations, such as service technicians or field engineers.

- Durability and power options: Handheld models typically run on batteries, which offer flexibility but may limit continuous use. Durable designs are essential for fieldwork, as the device needs to withstand varying environmental conditions.

- Benchtop models: These larger units are more powerful and suited for stationary use in lab environments. They offer higher precision, more features, and greater stability compared to their handheld counterparts, making them the preferred choice for detailed, long-term testing.

- Use case: Benchtop models are ideal for lab-based research, precision testing, or production environments where continuous, high-precision measurements are needed.

Ultimately, the choice between handheld and benchtop models comes down to the nature of your work. For portability and quick diagnostics, handheld counters excel, while benchtop models provide the robustness and precision required for more complex or long-term applications.

How to Select the Right Frequency Counter for Your Needs

Selecting the right frequency counter depends heavily on the type of engineering work you do and the specific applications you need to address. By assessing key factors like frequency range, resolution, and accuracy, you can match the right counter to your needs and avoid performance issues down the road.

- Frequency range: Start by determining the range of frequencies you’ll be measuring. If you’re working in RF or microwave communications, you’ll need a counter capable of handling higher frequencies, often in the gigahertz (GHz) range. On the other hand, audio engineers or technicians working with lower frequencies will only require a range of up to 20 kHz.

- Resolution: Consider the level of precision required for your tasks. For applications like low-frequency audio testing, high resolution is crucial to capture small changes in frequency. However, in higher-frequency applications like RF signal testing, slightly lower resolution can be acceptable if speed is a priority.

- Accuracy: Accuracy is essential for ensuring reliable, consistent readings over time. This is especially important in lab settings, where high-precision measurements are critical. For most high-accuracy applications, a counter with a stable internal oscillator, such as a TCXO (temperature-compensated crystal oscillator), is ideal.

- Portability: If you’re often in the field or working in multiple locations, portability becomes a priority. Handheld frequency counters offer flexibility for on-the-go testing, while benchtop models are better suited for long-term, lab-based measurements.

- Software compatibility: Ensure that the counter you choose integrates well with your existing systems. Many modern frequency counters can connect to external software for data logging or further analysis, which can streamline your workflow.

When balancing features with your budget, consider buying certified used equipment. Premium used frequency counters from companies like Keysight can offer high-end performance at a fraction of the cost, with warranties and calibration services included.

| Key Factor | Application | Frequency Counter Type |

|---|---|---|

| Frequency Range | RF, Microwave Communications | Reciprocal or Direct Counter |

| Resolution | Audio Testing, Low-Frequency Signals | High-Resolution Direct Counter |

| Accuracy | Lab Testing, Precision Measurements | Reciprocal Counter with TCXO |

| Portability | Field Testing, On-the-Go Measurements | Handheld Frequency Counter |

| Software Compatibility | Data Logging, Automated Testing | Counter with Digital Interface |

By carefully considering these factors, you can choose the right frequency counter for your specific needs while staying within your budget, especially when considering used equipment options.

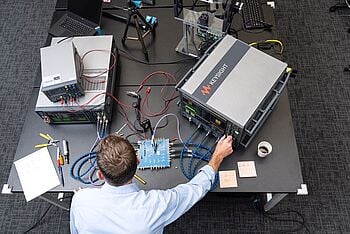

6 Tips for Buying a Used Frequency Counter

Buying a used frequency counter can be a cost-effective way to access high-quality equipment, especially if you know what to look for. With Keysight’s certified used portal, you can find well-maintained frequency counters that have been thoroughly tested and calibrated, offering performance that's as good as new.

Here are six key tips to ensure you get the best value when buying a used frequency counter.

1. Check the Calibration History

Before purchasing a used frequency counter, it’s essential to review its calibration history. Calibration ensures that the counter is providing accurate and reliable measurements, which is critical for engineering tasks. A well-maintained device will have undergone regular calibration, so make sure the seller provides detailed records.

- Why it matters: Without calibration, the counter’s accuracy can drift, leading to unreliable results.

- Keysight advantage: Keysight’s certified used equipment comes with a calibration certificate, ensuring that the device has been properly maintained and is ready for use.

2. Assess the Condition of Input Channels

Input channels are the key points where signals are fed into the frequency counter, so their condition is critical. When buying used, visually inspect the input channels for any signs of wear, corrosion, or damage. If possible, test the device to ensure the channels are fully operational.

- Tips: Check for any physical damage or wear on the connectors, as well as signs of signal loss during testing. Damaged input channels can lead to inaccurate readings.

- Keysight advantage: All used equipment from Keysight undergoes rigorous testing, ensuring that input channels are fully functional and free from damage.

3. Verify Software Compatibility

Modern frequency counters often integrate with software systems for data logging, automation, and analysis. Before purchasing a used frequency counter, make sure it is compatible with the software you use in your workflow. This is especially important for older models, which may not support newer software platforms.

- Why it matters: Software compatibility ensures that your frequency counter can integrate seamlessly with your existing systems, saving time and avoiding compatibility issues.

- Keysight advantage: Keysight provides detailed specifications and compatibility information, so you can verify that the used equipment will work with your current setup.

4. Factor in the Availability of Spare Parts

Some older models of frequency counters may have discontinued parts, making repairs and maintenance more difficult. Before purchasing, check whether spare parts for the model are still available. This will ensure that you can maintain the counter over time without facing difficulties in sourcing parts.

- Why it matters: If spare parts are unavailable, even minor repairs can become a significant challenge, leading to downtime.

- Keysight advantage: Keysight’s certified used equipment comes with access to spare parts and service support, ensuring long-term usability.

5. Source From a Reputable Reseller

The importance of sourcing from a reputable reseller cannot be overstated. Certified resellers like Keysight offer warranties, thorough testing, and calibration services, which give you confidence in the performance and reliability of the equipment. Avoid unknown sellers who may not offer proper warranties or guarantees.

- Why it matters: Buying from a trusted reseller ensures that the used equipment has been properly tested and maintained, reducing the risk of purchasing faulty or unreliable devices.

- Keysight advantage: Keysight’s certified used portal provides peace of mind, with warranties and comprehensive refurbishment and testing included in every purchase.

6. Compare Warranties and Return Policies

When buying used equipment, it’s important to compare warranties and return policies to protect your investment. Ensure the device comes with a warranty that covers potential defects or issues, and that the reseller has a return policy in place in case the equipment doesn’t meet your expectations.

- Why it matters: Warranties and return policies provide security, ensuring that you’re not stuck with faulty equipment or hidden issues.

- Keysight advantage: Keysight offers industry-leading KeysightCare on its certified used equipment, giving you confidence that your purchase is protected.

By following these tips, you can ensure that you get a high-quality used frequency counter that meets your needs without sacrificing performance or reliability.

Common Mistakes to Avoid When Buying a Frequency Counter

When purchasing a frequency counter, it’s important to be aware of some common pitfalls that can lead to poor performance or unexpected repair costs.

One of the biggest mistakes is buying solely based on price without considering key performance factors like frequency range, resolution, or accuracy. A cheaper model may seem like a good deal, but if it doesn't meet your engineering requirements, you’ll likely end up spending more time and money on troubleshooting or upgrades.

Another common pitfall is neglecting to check the condition of critical components, such as input channels and the internal oscillator. These parts directly impact the counter’s ability to deliver accurate results.

Lastly, skipping a calibration check is a costly error. An uncalibrated counter can drift in accuracy, leading to unreliable measurements and expensive repairs down the line.

Maintenance and Calibration Best Practices for Frequency Counters

To extend the lifespan of your frequency counter and ensure consistent accuracy, regular maintenance and calibration are key. Start by keeping the device clean and free from dust or debris, which can interfere with performance. Store it in a dry, temperature-controlled environment to protect it from humidity and temperature fluctuations, which can cause the internal components to degrade over time.

Perform regular calibration checks, ideally once a year or based on usage intensity. Calibration ensures the counter maintains its accuracy and should always be conducted by a certified professional. When the device is not in use, store it in its original protective case or a padded environment to prevent accidental damage. By following these best practices, you’ll keep your frequency counter in top working condition for years to come.

Measure with Confidence Using the Perfect Frequency Counter

Choosing the right frequency counter doesn’t have to be a source of frustration. By carefully considering factors like frequency range, resolution, accuracy, and input sensitivity, you can avoid the common pitfalls that lead to inconsistent or unreliable measurements.

Whether you’re tackling low-frequency audio signals or high-frequency RF applications, having a tool that’s calibrated, well-maintained, and suited to your needs is essential for precision and efficiency.

At Keysight, we understand the importance of getting accurate readings when it counts. Our certified used frequency counters offer the reliability of new equipment at a fraction of the cost, backed by calibration, warranties, and full testing. Whether you need portability for fieldwork or a benchtop model for lab precision, we’ve got you covered.

Don’t let uncertainty or outdated equipment hold you back. With our range of premium options, you can invest in the tools you need to deliver reliable results—every time.

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our premium used network analyzers, oscilloscopes, signal analyzers and waveform generators

- Call tech support US: 1 800 829-4444. Press #, then 2. Hours: 7 am – 5 pm MT, Mon– Fri

- Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists

- Talk to your account manager about your specific needs.