- Introduction

- What is a Potentiometer?

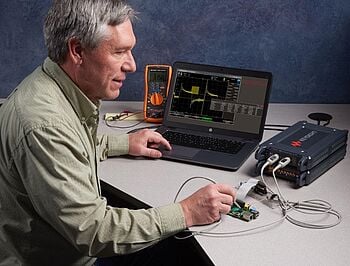

- Secure Your Project's Success with Keysight's Trusted, Refurbished Equipment

- How Do Potentiometers Work?

- Types of Potentiometers

- Rotary Potentiometer

- Linear Potentiometer

- Slider Potentiometer

- Trimmer Potentiometer

- Digital Potentiometer

- Potentiometers vs. Rheostats

- How to Choose the Right Potentiometer

- Basic Wiring Techniques

- Wiring Configurations

- Advanced Wiring Configurations

- Troubleshooting Common Issues

- Potentiometer Calibration and Testing

- Calibration Methods

- Testing Methods

- Optimize Your Projects with the Perfectly Calibrated Potentiometer

- Get the Best Results with Keysight's Refurbished Equipment

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

Ever been knee-deep in a project only to have your potentiometer fail you? Picture this: you’re designing a joystick for a remote-controlled robot used in hazardous environments. You need accurate position feedback to ensure smooth and responsive control. However, the potentiometer you selected produces jittery signals, making the robot’s movements unpredictable and potentially dangerous. Frustrating, right?

Engineers often grapple with these kinds of challenges. Selecting the right potentiometer and wiring it correctly can make or break your project. Whether you’re working on robotics, aerospace, or precision instrumentation, the reliability and accuracy of your potentiometer are crucial.

In this guide, we’ll walk you through the ins and outs of choosing the perfect potentiometer and wiring it like a pro.

We’ll cover different types, their specific uses, and share practical wiring tips to simplify your setup. With real-world examples and expert advice, this guide will help you conquer potentiometer problems with confidence, ensuring your project performs flawlessly.

What is a Potentiometer?

A potentiometer is a three-terminal variable resistor that allows for adjustable voltage division in an electrical circuit. It functions by varying the resistance along its length, providing a way to control the output voltage.

The main components of a potentiometer include the resistor body, wiper, and terminals.

- Resistor body: This is a resistive element, typically made of carbon, cermet, or a conductive plastic. It provides a path for current and varies in resistance.

- Wiper: The wiper is a movable contact that slides along the resistive element. It divides the resistor body into two sections, creating a variable resistance depending on its position.

- Terminals: A potentiometer has three terminals: two connected to the ends of the resistor body and one connected to the wiper. By adjusting the wiper position, you can vary the resistance between the wiper and each end terminal, thus adjusting the output voltage.

Historically, potentiometers have evolved from simple rheostats used in early radio and telecommunication devices to sophisticated components in modern electronics. Initially, they were large and cumbersome, but advancements in materials and manufacturing techniques have made them more compact and precise.

Today, potentiometers are integral in various applications, from volume controls in audio equipment to position sensors in industrial machinery, showcasing their versatility and enduring relevance in electronic design.

Secure Your Project's Success with Keysight's Trusted, Refurbished Equipment

Select up to 3 instruments to compare

How Do Potentiometers Work?

A potentiometer operates by physically altering the path of electrical resistance within a circuit. The key mechanism involves the movement of a wiper along a resistive element.

Physical Mechanism of Action

The resistive element is a fixed component with a specific resistance value, typically shaped as a curved or straight track. The wiper, which is a sliding or rotating contact, moves along this track. When you turn the potentiometer’s knob or slide its lever, the wiper moves, changing its position along the resistive element.

Electrical Resistance and Adjustment

Electrical resistance is the opposition to the flow of current through a material. In a potentiometer, the resistive element provides this opposition. The potentiometer has three terminals: two at the ends of the resistive element and one connected to the wiper.

When the wiper moves:

- It changes the length of the resistive path between one end terminal and the wiper.

- The resistance between the wiper and each end terminal varies inversely; as the wiper moves closer to one terminal, the resistance to that terminal decreases, and the resistance to the opposite terminal increases.

This adjustment alters the voltage drop across each section of the resistive element. By varying the position of the wiper, you can precisely control the output voltage at the wiper terminal.

This ability to finely tune the voltage is why potentiometers are invaluable in applications requiring variable control, such as adjusting volume levels, tuning circuits, and setting reference voltages.

Types of Potentiometers

Potentiometers come in various types, each designed for specific applications and environments. The choice of potentiometer depends on the required motion, space constraints, and the nature of the control needed. Let's explore some common types, starting with rotary potentiometers.

Rotary Potentiometer

A rotary potentiometer features a resistive element arranged in a circular arc. The wiper, attached to a rotating shaft, moves along this arc. As you turn the shaft, the wiper travels across the resistive element, altering the resistance and, consequently, the output voltage. The shaft typically has a knob or dial for user input, making it easy to adjust the resistance.

Common Uses

Rotary potentiometers are widely used in both consumer electronics and industrial applications. In consumer electronics, they are commonly found in devices like audio equipment for volume control, tone adjustment, and balance settings.

In industrial settings, rotary potentiometers are used in control systems for adjusting speed, position, or other parameters in machinery and instrumentation. Their ability to provide precise control over electrical characteristics makes them indispensable in various automated and manual control applications.

Linear Potentiometer

A linear potentiometer, also known as a slider potentiometer, features a resistive element arranged in a straight line. The wiper moves linearly along this element, altering the resistance based on its position. The linear motion provides a direct relationship between the position of the wiper and the resistance, making it straightforward to achieve precise adjustments.

Typical Applications

Linear potentiometers are commonly used in applications where straight-line movement is more practical than rotation. They are often found in measuring devices, where they convert mechanical displacement into an electrical signal.

They are ideal for position sensing in robotics, automotive throttle control, and industrial machinery. Their linear movement is particularly advantageous in scenarios requiring direct and proportional control, such as in drawing tablets and various types of control panels.

Slider Potentiometer

Slider potentiometers are a subtype of linear potentiometers distinguished by their user-friendly interface, which involves a sliding knob that moves along a track.

Unlike traditional linear potentiometers that may be more compact, slider potentiometers are designed for easy and intuitive manual adjustment.

Popular Uses

Slider potentiometers are prominently used in sound mixing boards, where precise control over audio levels is essential. The long, linear movement allows for fine-tuning of audio signals, making them a staple in professional audio equipment.

They are also widely used in lighting controls, providing smooth and gradual adjustment of light intensity. The visual and tactile feedback of slider potentiometers makes them ideal for applications requiring frequent and precise adjustments.

Trimmer Potentiometer

Trimmer potentiometers, or trimpots, are small, adjustable potentiometers designed for fine-tuning and calibration within electronic circuits. Their compact size allows them to fit easily onto printed circuit boards (PCBs), often used as a part of the calibration process in manufacturing and maintenance.

Primary Use

The main application of trimmer potentiometers is in circuit tuning and calibration. They are used to make small, precise adjustments to the performance of an electronic circuit, such as setting the biasing levels in amplifiers or tuning the frequency of oscillators.

Once set, they are typically not adjusted, ensuring stable operation over time. Their precision and stability make them invaluable in applications requiring exact control.

Digital Potentiometer

Digital potentiometers, also known as digipots, operate based on digital signals rather than mechanical movement.

They use an array of resistors and electronic switches controlled by digital input signals, usually interfaced via protocols like I²C or SPI. This allows for precise control over the resistance value through software commands.

Advantages

Digital potentiometers offer several advantages over their mechanical counterparts. They provide high precision and repeatability, as the resistance values are set electronically without the variability of mechanical wear and tear.

Their ability to be easily adjusted and integrated into automated systems makes them perfect for situations requiring frequent remote adjustments.

Potentiometers are commonly used in digital audio systems, automated test equipment, and other applications requiring precise and reliable control.

Potentiometer Types Comparison

| Type | Features | Advantages | Typical Applications |

|---|---|---|---|

| Rotary Potentiometer | Circular motion, knob or dial for adjustment | Durable, precise control | Volume control in audio equipment, industrial control systems |

| Linear Potentiometer | Straight-line motion, proportional control | Direct and proportional control | Position sensing in robotics, automotive throttle control |

| Slider Potentiometer | Sliding knob, user-friendly interface | Intuitive, easy manual adjustment | Sound mixing boards, lighting controls |

| Trimmer Potentiometer | Compact size, fine-tuning adjustment | Precise, stable, small form factor | Circuit tuning and calibration, setting biasing levels |

| Digital Potentiometer | Digital signals, no mechanical movement | High precision, programmable, no wear | Digital audio systems, automated test equipment |

Potentiometers vs. Rheostats

Potentiometers and rheostats are both devices designed to adjust resistance within an electrical circuit, but they serve different purposes and have distinct constructions.

Function and Application

Potentiometers are primarily used for voltage division. They have three terminals: two connected to the ends of a resistive element and one connected to a movable wiper.

By adjusting the wiper's position, you can vary the resistance between the wiper and the end terminals, dividing the voltage across the resistive element. This makes potentiometers ideal for applications where precise control of voltage is needed, such as in volume controls and tuning circuits.

In contrast, rheostats are used for controlling current. They typically have two terminals: one connected to one end of the resistive element and the other connected to the wiper.

By varying the wiper's position along the resistive element, the resistance in the circuit changes, controlling the current flow. Rheostats are often found in applications requiring current adjustment, such as in light dimmers and motor speed controls.

Construction Differences

The key difference in construction lies in the terminal configuration. Potentiometers have three terminals that allow them to function as adjustable voltage dividers. Rheostats only have two terminals and are designed to handle higher power and to vary current.

Rheostats are built to withstand higher power dissipation compared to potentiometers, making them suitable for applications involving significant current flow.

While both devices adjust resistance, potentiometers are best for precise voltage control, and rheostats are suited for regulating current in a circuit.

How to Choose the Right Potentiometer

When selecting a potentiometer, consider the following key factors to ensure it meets your application’s requirements:

- Resistance value: Choose a resistance value that matches your circuit needs. Common values range from a few ohms to several megaohms. Ensure the selected value provides the desired range of control.

- Tolerance: Check the tolerance specification, which indicates how much the actual resistance can vary from the stated value. Lower tolerance (e.g., ±1%) offers higher precision, while higher tolerance (e.g., ±20%) is less precise.

- Physical size: Ensure the potentiometer fits the available space in your device. Consider the form factor, such as rotary, linear, or trimmer types, based on your design constraints and user interface needs.

- Power rating: Verify the potentiometer’s power rating to ensure it can handle the power levels in your application without overheating or failing. This is crucial for applications involving high current or voltage.

- Nature of the application: Select a potentiometer type suited to your application. For example, choose rotary potentiometers for audio equipment, linear potentiometers for position sensing, and trimmer potentiometers for circuit calibration.

Tips for Evaluating Quality and Reliability

- Material quality: Opt for potentiometers made from high-quality materials, such as conductive plastic or cermet, for better durability and performance.

- Environmental resistance: Ensure the potentiometer can withstand the environmental conditions it will be exposed to, such as temperature variations, humidity, and mechanical vibrations.

- Lifespan and durability: Check the specified lifespan, often given in the number of cycles, to ensure it meets the longevity requirements of your application.

By considering these factors and tips, you can select a potentiometer that delivers reliable performance and suits your specific needs.

Basic Wiring Techniques

A potentiometer must be wired correctly for it to function in a circuit. Here’s a detailed guide on how to wire a potentiometer, including common configurations.

Three-Terminal Setup

The most common wiring configuration for a potentiometer involves three terminals:

- Terminal 1: One end of the resistive element.

- Terminal 2 (Wiper): The adjustable middle terminal.

- Terminal 3: The other end of the resistive element.

Steps for Wiring

- Identify terminals: Locate the three terminals on the potentiometer. Terminals 1 and 3 are on the ends, and terminal 2 (the wiper) is in the middle.

- Connect terminal 1 to input voltage( Vcc).

- Connect terminal 3 to ground: (GND).

- Connect terminal 2 to output: the output of your circuit where you need the variable voltage.

Wiring Configurations

Voltage Divider Configuration

- Terminal 1 to Vcc.

- Terminal 3 to GND.

- Terminal 2 (wiper) to the output. This setup divides the input voltage based on the wiper position.

Rheostat Configuration (Two-Terminal)

- Use terminals 1 and 2 (or 2 and 3) for a two-terminal setup.

- Connect terminal 1 to the circuit input.

- Connect terminal 2 (wiper) to the circuit output. This configuration adjusts the current flowing through the circuit by varying the resistance.

Advanced Wiring Configurations

When using potentiometers in more complex applications, there are several advanced wiring configurations to consider. These setups can enhance functionality and integrate potentiometers with other electronic components like microcontrollers.

Precision Voltage Divider

- Purpose: Achieve precise voltage division for sensitive applications.

Configuration:

- Terminal 1 to Vcc.

- Terminal 3 to GND.

- Terminal 2 (wiper) to a high-impedance input (e.g., an analog-to-digital converter, ADC, on a microcontroller).

- Application: Use in signal conditioning circuits to adjust sensor outputs.

Potentiometer with Buffer Amplifier

- Purpose: Isolate the potentiometer from the load to prevent loading effects.

Configuration:

- Connect the potentiometer in a standard voltage divider setup.

- Connect the wiper (Terminal 2) to the input of an operational amplifier (op-amp) configured as a buffer (voltage follower).

- Application: Use in audio applications to maintain signal integrity.

Dual Potentiometers for Differential Measurement

- Purpose: Measure the difference between two signals.

Configuration:

- Use two potentiometers, each configured as a voltage divider.

- Connect the wipers of both potentiometers to the inputs of a differential amplifier.

- Application: Use in applications requiring precise differential measurements, such as strain gauge circuits.

Microcontroller Integration

- Purpose: Interface potentiometers with microcontrollers for digital control and monitoring.

Configuration:

- Terminal 1 to Vcc.

- Terminal 3 to GND.

- Terminal 2 (wiper) to an ADC pin on the microcontroller.

- Application: Use in user interfaces for adjusting parameters digitally, such as setting thresholds or tuning control loops.

Feedback Control Loop

- Purpose: Implement feedback in control systems.

Configuration:

- Use the potentiometer as a position or angle sensor.

- Connect the wiper to an ADC input on a microcontroller.

- Use the ADC reading in the microcontroller's control algorithm to adjust actuators.

- Application: Use in robotic arms or servo mechanisms to provide accurate position feedback.

These advanced configurations expand the versatility of potentiometers, allowing precise control, integration with digital systems, and improved performance in complex circuits.

Troubleshooting Common Issues

When using potentiometers, problems can arise, potentially affecting their performance and reliability. Here are some practical troubleshooting steps to address these issues.

Electrical Noise

- Issue: Potentiometers can introduce electrical noise into circuits, leading to unstable signals.

- Solution: Use a capacitor across the potentiometer terminals to filter out high-frequency noise. Ensure proper grounding and shielding of the potentiometer and associated wiring.

- Tip: Use spectrum analyzers to identify and characterize noise sources in circuits with potentiometers.

Wear and Tear

- Issue: Over time, the mechanical movement of the wiper can cause wear on the resistive element, leading to inconsistent resistance and performance degradation.

- Solution: Regularly inspect potentiometers for signs of wear. Replace worn-out potentiometers to maintain performance. Consider using higher-quality potentiometers with better materials for critical applications.

Contact Issues

- Issue: Poor contact between the wiper and resistive element can cause intermittent signals or dead spots.

- Solution: Clean the potentiometer contacts with a suitable electronic contact cleaner. Ensure the potentiometer is not subjected to excessive mechanical stress that could dislodge the wiper.

Common Potentiometer Issues and Solutions

| Issue | Problem | Solution |

|---|---|---|

| Electrical Noise | Unstable signals due to noise interference | Use capacitors for filtering, ensure proper grounding, use Keysight spectrum analyzers |

| Wear and Tear | Inconsistent resistance from mechanical wear | Inspect regularly, replace worn-out units, use high-quality materials |

| Contact Issues | Intermittent signals or dead spots | Clean contacts, avoid mechanical stress, ensure proper installation |

Potentiometer Calibration and Testing

Accurate readings from potentiometers require regular calibration and testing. Here are some methods and tools for achieving precise calibration:

Calibration Methods

Manual Calibration:

- Description: Adjust the potentiometer while measuring its output voltage or resistance until it matches the desired value. This method is simple but relies on the accuracy of the measuring instruments.

- Tools needed: Multimeter, reference voltage source or known resistance.

Automated Calibration:

- Description: Use automated test equipment to calibrate the potentiometer by adjusting it under controlled conditions and comparing the output to pre-set standards.

- Tools Needed: Automated test systems, software for control and measurement.

Testing Methods

Using a Multimeter

- Resistance testing: Connect the multimeter probes to the potentiometer terminals to measure resistance. Rotate the shaft and observe the changes in resistance to ensure smooth variation without dead spots.

- Continuity testing: Check for continuity between the wiper and end terminals to detect any breaks or inconsistencies.

Using an LCR Meter

Measure the inductance (L), capacitance (C), and resistance (R) of the potentiometer with high precision. This method provides detailed insights into the potentiometer’s performance, including linearity and tolerance.

Recommended Tools

Keysight offers a variety of high-precision multimeters and LCR meters suitable for calibrating and testing potentiometer parameters like resistance, tolerance, and linearity. These tools provide accurate and reliable measurements, ensuring your potentiometers perform optimally.

“For all used equipment, I offer my clients calibration and 1-year warranty.” – Keysight Account Manager

Optimize Your Projects with the Perfectly Calibrated Potentiometer

Accurate potentiometer performance is crucial for your projects. From addressing electrical noise to ensuring precise resistance control, we’ve covered essential tips for selecting, wiring, and maintaining potentiometers.

Remember that frustrating moment when your potentiometer caused erratic joystick movements in your remote-controlled robot? By mastering potentiometer selection, wiring, and maintenance, you can avoid such pitfalls.

Leveraging top-tier testing equipment from Keysight, you can achieve consistent, reliable results. Our products make accurate measurements accessible and affordable, empowering you to create with confidence.

Say goodbye to unreliable potentiometers and hello to precise control in your projects. With Keysight’s tools, reliable test results are within your reach.

Get the Best Results with Keysight's Refurbished Equipment

Select up to 3 instruments to compare

Enable Notifications

In order to use this feature, you need to enable notifications.

Manage notification preferences

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our premium used network analyzers, oscilloscopes, signal analyzers and waveform generators.

- Call tech support US: 1 800 829-4444

Press #, then 2. Hours: 7am – 5pm MT, Mon– Fri - Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists.

- Talk to your account manager about your specific needs