- Introduction

- Definition of a Short Circuit

- Causes of Short Circuits

- Effects of Short Circuits

- Types of Short Circuits

- Line-to-Line Short Circuit

- Line-to-Ground Short Circuit

- Three-Phase Short Circuit

- Identifying and Testing Short Circuits

- Visual Inspection

- Multimeter Testing

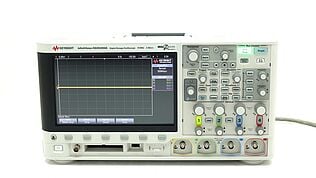

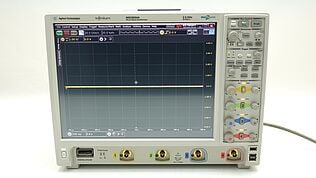

- Oscilloscope Testing

- Additional Testing Tools and Techniques

- Best Practices for Testing

- Preventing Short Circuits

- Design Considerations

- Maintenance Practices

- Comparison of Protection Devices

- Conclusion

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

Picture this: you're in the middle of a test with your oscilloscope when, out of nowhere, the circuit you're working on suddenly stops functioning, and a faint smell of burning plastic fills the air.

You've just encountered a short circuit, a common issue that can cause extensive damage if not properly understood and managed.

Knowing how to identify, test, and prevent short circuits is essential for maintaining the safety and efficiency of your electrical systems.

Definition of a Short Circuit

A short circuit occurs when an unintended path with low resistance is created in an electrical circuit, allowing excessive current to flow. This can result in overheating, damage to components, and even fires.

| Key Takeaway |

|---|

| Understanding and effectively diagnosing short circuits is crucial for maintaining the safety and functionality of electrical systems. Using the right tools and techniques, such as visual inspections, multimeters, and oscilloscopes, can help you identify and prevent these issues efficiently. |

Explore Keysight’s Range of Oscilloscopes Today

Causes of Short Circuits

Several factors can cause short circuits, including:

- Faulty wiring: Damaged or improperly installed wires can create unintended connections.

- Insulation failure: Deteriorated or damaged insulation can lead to direct contact between conductors.

- Loose connections: Poorly secured connections can result in unintended contact.

- External factors: Water intrusion, physical damage, or pests can compromise the integrity of an electrical system.

Effects of Short Circuits

Short circuits can have serious consequences, such as:

- Overheating: Excessive current flow can cause components to overheat.

- Component damage: Sensitive electronic components can be destroyed by high currents.

- Fire hazards: Overheating can ignite surrounding materials resulting in a fire.

- System failure: A short circuit can lead to complete failure of the electrical system.

Types of Short Circuits

Understanding the different types of short circuits helps in diagnosing and preventing them. Each type has unique characteristics and potential impacts on electrical systems.

Line-to-Line Short Circuit

A line-to-line short circuit occurs when two conductors carrying current come into direct contact with each other.

This type of short circuit is particularly dangerous because it allows a large amount of current to flow through a very low resistance path, often resulting in significant damage.

Common causes of line-to-line short circuits include damaged insulation, improper wiring, and physical damage to the conductors.

Line-to-Ground Short Circuit

In a line-to-ground short circuit, a conductor carrying current comes into contact with the ground or a grounded part of the system. This type of short circuit is usually caused by insulation failure, which can occur due to aging, mechanical damage, or environmental factors such as moisture.

- Effects: A line-to-ground short circuit can create a direct path for current to flow to the ground, leading to potential shock hazards and damage to the electrical system.

- Detection: Ground fault circuit interrupters (GFCIs) are often used to detect and protect against line-to-ground short circuits by interrupting the circuit when a ground fault is detected.

Three-Phase Short Circuit

Three-phase systems can experience more complex short circuits, such as phase-to-phase or phase-to-ground short circuits. These are typically more severe due to the higher power involved.

- Phase-to-phase short circuit: This occurs when two of the three phases come into direct contact. The resulting current flow can be extremely high, causing significant damage and potential system failure.

- Phase-to-ground short circuit: This happens when one of the phases comes into contact with the ground. Similar to line-to-ground short circuits in single-phase systems, this can lead to ground faults and pose shock hazards.

Three-phase short circuits can be particularly challenging to manage because they often involve higher voltages and currents, making the potential for damage much greater.

Preventative measures include using proper insulation, regular maintenance, and protective devices like circuit breakers and fuses designed for three-phase systems.

Identifying and Testing Short Circuits

Identifying and testing for short circuits is crucial to maintaining the safety and functionality of electrical systems. Various methods and tools can help you pinpoint and diagnose these issues accurately.

Visual Inspection

Start with a thorough visual inspection to look for obvious signs of damage, such as burnt components, melted insulation, or discolored parts. Physical damage often indicates the presence of a short circuit. Here’s what to look for:

- Burn marks: Check for scorch marks around connectors, wires, and components.

- Melted insulation: Look for any signs of melted or deformed insulation on wires.

- Loose connections: Inspect for any loose or corroded connections that might cause unintended contact.

Multimeter Testing

Using a multimeter, you can check for continuity and measure resistance, which helps in identifying short circuits. Follow these steps:

- Choose correct mode: Set the multimeter to the continuity or resistance mode.

- Disconnect power: Ensure the circuit is de-energized to prevent damage to the multimeter and for your safety.

- Measure resistance: Place the multimeter probes across different points in the circuit. A very low resistance reading often indicates a short circuit.

- Check continuity: In continuity mode, the multimeter will beep if there is a direct path (short circuit) between the points being tested.

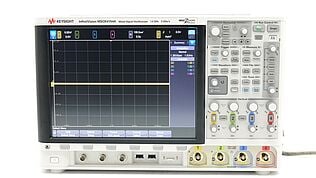

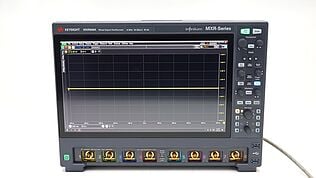

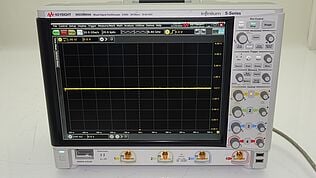

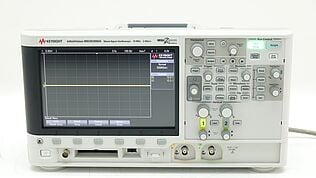

Oscilloscope Testing

Oscilloscopes can help visualize the electrical signals in a circuit, making it easier to spot anomalies that may indicate a short circuit. Here’s how to use an oscilloscope for testing:

- Connect the oscilloscope probes: Attach the probes to the points in the circuit you want to test.

- Power on the circuit: If safe to do so, power on the circuit to observe the signal behavior.

- Analyze the waveform: Look for irregularities in the waveform, such as sudden spikes or drops in voltage, which can indicate a short circuit.

- Compare with known good signals: If possible, compare the observed waveform with a known good signal to identify discrepancies.

Additional Testing Tools and Techniques

Besides multimeters and oscilloscopes, you can use other tools and techniques to identify and test for short circuits:

- Circuit tracers: These devices help trace the path of a circuit, making it easier to locate the point of failure.

- Insulation resistance testers: These testers apply a high voltage to measure the resistance of the insulation, helping identify potential insulation failures.

- Thermal imaging cameras: By detecting heat patterns, thermal cameras can help locate hotspots that may indicate a short circuit.

Best Practices for Testing

To ensure accurate and safe testing, follow these best practices:

- De-energize the circuit: Always turn off and disconnect power before testing to avoid electric shock and equipment damage.

- Use the right tools: Ensure you have the appropriate testing equipment for the specific type of circuit and short circuit you are diagnosing.

- Document findings: Keep detailed records of your testing results to help with future diagnostics and maintenance.

Preventing Short Circuits

Preventing short circuits involves proper design, regular maintenance, and using appropriate protection devices.

Design Considerations

- Proper insulation: Use high-quality insulation materials.

- Correct wiring: Follow standards and guidelines for wiring installations.

- Adequate spacing: Ensure sufficient spacing between conductors.

Maintenance Practices

- Regular inspections: Conduct periodic inspections of the electrical system.

- Timely repairs: Address any signs of wear or damage immediately.

- Environmental control: Keep the electrical environment clean and dry.

Comparison of Protection Devices

| Protection Device | Function | Advantages | Disadvantages |

|---|---|---|---|

| Circuit Breakers | Interrupts excessive current | Reusable, quick response | Higher cost |

| Fuses | Breaks circuit under overcurrent | Inexpensive, simple | One-time use, slower response |

| GFCIs | Detects ground faults | Enhances safety, prevents shocks | Can be prone to nuisance trips |

By understanding and addressing the causes, effects, and prevention methods of short circuits, you can ensure the safety and reliability of your electrical systems. Always use appropriate testing equipment and follow safety protocols to mitigate risks effectively.

Maximize Your Budget with Keysight's Refurbished Oscilloscopes

Select up to 3 instruments to compare

Enable Notifications

In order to use this feature, you need to enable notifications.

Manage notification preferences

Conclusion

Short circuits are a common but critical issue in electrical systems, leading to potential damage and safety hazards. Understanding the different types of short circuits—line-to-line, line-to-ground, and three-phase—is essential for effective diagnosis and prevention.

Using visual inspections, multimeter testing, and oscilloscope analysis, you can accurately identify and address short circuits. Regular maintenance and the use of protective devices further improve system safety and reliability.

For top-quality testing equipment, consider the Keysight Used Equipment Store. Offering premium used oscilloscopes, network analyzers, function generators, and multimeters to ensure you have the tools needed for precise diagnostics and maintenance. Visit the Keysight Used Equipment Store today and equip yourself with the best tools for the job

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our Premium Used Oscilloscopes.

- Call tech support US: +1 800 829-4444

Press #, then 2. Hours: 7 am – 5 pm MT, Mon– Fri - Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists.

- Talk to your account manager about your specific needs.