- Introduction

- Digital Instruments Defined

- Why the Shift to Digital?

- Key Digital Instruments Every Electrical Engineer Should Know

- Digital Multimeters (DMM)

- Digital Oscilloscopes

- Logic Analyzers

- Spectrum Analyzers

- Network Analyzers

- Comparing Key Features of Digital Instruments

- Delving Deeper: The Underlying Technology

- Analog-to-Digital Conversion (ADC)

- Digital Signal Processing (DSP)

- Display Technology

- Connectivity and Storage

- Calibration and Accuracy in Digital Instruments

- Why is Calibration Important?

- Manual vs. Auto-Calibration

- Conclusion

- Whenever You’re Ready, Here Are 5 Ways We Can Help You

Imagine a world where electrical engineers relied solely on analog tools, trying to decipher readings from moving needles and constantly calibrating their devices. This was the reality until the early 1950s. The first digital voltmeter was introduced in those years, marking a transformative shift in the way we measure and understand electronic signals.

Since that groundbreaking moment, digital instruments have not just been on the rise; they have drastically evolved. Today, these devices do more than just display numbers. They visualize, analyze, and even predict, offering insights and precision that were once thought impossible. Let's explore the intricate world of digital instruments, unraveling their workings, and their undeniable importance in modern electronics.

Buy Oscilloscopes at a Great Discount

Digital Instruments Defined

Digital instruments are devices that measure, analyze, or manipulate signals and data in a digital form, as opposed to analog instruments which represent data in a continuous form. The fundamental difference between digital and analog tools is the manner in which they process and display data.

Why the Shift to Digital?

- Precision: Digital instruments generally offer greater precision than their analog counterparts.

- Flexibility: Advanced features such as digital signal processing, data storage, and remote control are easier to implement on digital platforms.

- Readability: Digital displays are generally easier to read and interpret than analog dials.

- Integration: Digital devices can be easily integrated into larger systems, facilitating complex measurements and automation.

| Key Takeaway |

|---|

| Digital instruments stand as the cornerstone of electrical engineering, transforming abstract concepts into tangible data, and playing a pivotal role in driving the very pulse of technological evolution and innovation. |

Key Digital Instruments Every Electrical Engineer Should Know

Digital Multimeters (DMM)

Often hailed as the Swiss army knife of an electrical engineer’s toolkit, digital multimeters (DMM) are versatile and essential. These instruments are designed to measure a variety of parameters such as voltage, current, and resistance. Some advanced models also delve into measuring frequency, capacitance, and even temperature.

Their core advantage is their precision. Unlike their analog counterparts which depend on the interpretation of needle positions, DMMs provide precise digital readouts, eliminating reading errors. They combine the functionalities of multiple analog meters into one compact device, making them both practical and efficient for on-the-spot diagnostics.

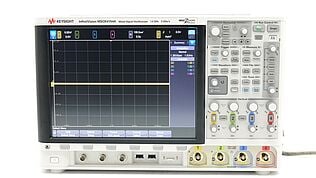

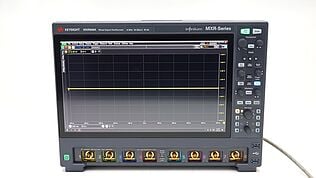

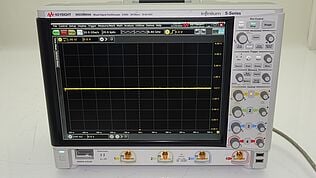

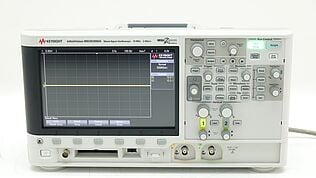

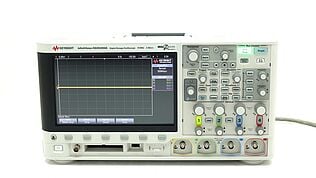

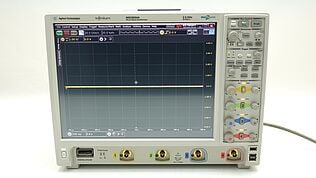

Digital Oscilloscopes

Digital Oscilloscopes are to electrical engineers what heartbeat monitors are to doctors. They provide a visual representation of electrical signals, displaying how these signals change over time. By mapping out these waveforms, engineers can gain insights into the behavior of electronic devices.

The primary function of oscilloscopes is to measure frequency, amplitude, and other properties of signals. Their standout feature is their ability to capture non-repeating or transient waveforms, something their analog predecessors struggled with. This means that engineers can capture, store, and analyze waveforms over extended periods, which is beneficial especially when troubleshooting intermittent issues.

Logic Analyzers

When delving deep into the world of digital circuits, logic analyzers become the tool of choice. They are designed specifically to monitor, capture, and display multiple signals from digital systems or circuits. Think of them as supercharged oscilloscopes tailored for digital applications. Their primary advantage is their role in debugging.

Digital circuits, with their myriad of interconnected components, can be challenging to troubleshoot. Logic analyzers simplify this process by offering a detailed view of many signals simultaneously, ensuring that engineers can spot discrepancies or errors in the digital logic flow, making the verification of digital systems a more streamlined process.

Spectrum Analyzers

While oscilloscopes visualize time-domain signals, spectrum analyzers dive into the frequency domain, allowing engineers to view the frequency content of signals. Every signal, from the simple sine wave to the most complex waveform, comprises multiple frequencies.

Spectrum analyzers break down these signals to display their constituent frequencies. By doing so, they help engineers identify elements like noise, interference, and harmonics. This is especially crucial in fields like radio frequency (RF) design and communication, where signal integrity is paramount.

Network Analyzers

These instruments measure the complex network parameters of electrical networks. When working with high-frequency components, understanding parameters like amplitude, phase, and impedance is crucial.

Network analyzers delve into these metrics, particularly focusing on S-parameters which are pivotal in RF applications. They play a decisive role in evaluating and optimizing the performance of networks and components. Whether designing an antenna, a filter, or any other RF component, network analyzers provide the data needed to ensure optimal performance.

Comparing Key Features of Digital Instruments

| Instrument | Primary Function | Key Advantage |

| Digital Multimeter | Measure multiple electrical properties | Multi-functionality and precision |

| Oscilloscope | Display waveforms over time | Visualize and analyze signal behavior |

| Logic Analyzer | Monitor digital circuits | Debugging and verification |

| Spectrum Analyzer | Analyze frequency content | Detect and measure signal characteristics |

| Network Analyzer | Measure network parameters | Optimize network performance |

Delving Deeper: The Underlying Technology

Behind the polished screens and straightforward buttons of digital instruments lies a matrix of intricate technology. Let's explore the crux of these systems that empower our instruments.

Analog-to-Digital Conversion (ADC)

At the heart of every digital instrument is the analog-to-digital converter (ADC). As its name suggests, it bridges the gap between the analog world of continuous signals and the digital realm of discrete values. Let’s break this down:

- Sample rate: Essentially, the ADC takes 'snapshots' of an incoming analog signal at regular intervals. The frequency at which these snapshots are taken is the sample rate. A higher sample rate means more snapshots in a given time, leading to a more accurate representation of the analog signal.

- Resolution: Think of resolution as the 'depth' of each snapshot. A higher resolution means that each sample contains more detailed information about the signal at that instant. For example, an 8-bit resolution can represent the signal level with 256 different values, while a 16-bit resolution boosts this to 65,536 values.

Digital Signal Processing (DSP)

Once we have our analog signals safely converted into digital form, digital signal processing (DSP) takes the helm. This powerful technology processes these signals to enhance, filter, or even transform them in several ways.

The standout benefit of DSP is its ability to process signals in real-time. This means that engineers can monitor, analyze, and even adjust signal parameters on-the-fly.

Applications:

- Noise reduction: DSP can be employed to filter out unwanted interference, ensuring clean and clear signals.

- Signal enhancement: It can amplify certain aspects of a signal while suppressing others.

- Data compression: DSP techniques can be used to compress data, making it easier to store or transmit without significant loss of information.

Display Technology

The progress in display technology mirrors the evolution of digital instruments. What began as rudimentary monochromatic CRTs has now blossomed into vibrant, high-definition displays:

- OLED and TFT displays: Modern digital instruments predominantly employ OLED and TFT display technologies. These offer sharper, clearer, and more energy-efficient visualization than their predecessors.

- Touchscreen interfaces: The integration of touchscreen technology into digital instruments has revolutionized user interaction. Instead of a myriad of buttons and dials, engineers can now navigate menus, adjust settings, and even sketch directly on the display.

Connectivity and Storage

The modern age is all about being connected. Digital instruments are no exception. They're designed to store vast amounts of data, share this data with other devices, and even be operated remotely.

- USB and Ethernet ports: The inclusion of these ports has made data transfer a breeze. Whether it's offloading captured waveforms from an oscilloscope or updating firmware, these ports are vital.

- Wi-Fi and Bluetooth: Wireless technology has made cables redundant in many applications. Instruments can now connect to networks, share data with cloud storage, or even be operated using smartphones and tablets.

Calibration and Accuracy in Digital Instruments

In the realm of digital instruments, calibration ensures that the readings we trust, the values we base our decisions on, are both accurate and reliable. Dive a little deeper, and it becomes clear why calibration is a cornerstone in the world of digital instrumentation.

Why is Calibration Important?

- Ensuring reliability: Engineers and technicians rely heavily on digital instruments to make decisions, design circuits, or troubleshoot issues. Calibration ensures that these instruments provide reliable data, leading to accurate assessments and solutions.

- Maintaining standards: Many industries have strict standards and regulations to ensure product quality and safety. Calibration ensures that digital instruments adhere to these standards, preventing potential mishaps or failures.

- Longevity of instruments: Instruments drift over time due to various factors, including wear and tear, environmental conditions, and component aging. Regular calibration compensates for this drift, ensuring the instrument's longevity and consistent performance.

Manual vs. Auto-Calibration

- Manual calibration: Traditionally, calibration involved using known reference values and manually adjusting the instrument until it matched these references. This method, while effective, can be time-consuming and requires a skilled technician. It's crucial to have reference standards that are themselves calibrated and are of higher precision than the instrument being calibrated.

- Auto-calibration: Modern instruments come equipped with auto-calibration features. Leveraging internal or external standards, these devices can calibrate themselves at the push of a button. Not only does this save time, but it also minimizes human errors that might creep in during the calibration process. Some advanced instruments even possess self-diagnosing capabilities, alerting users when they drift from calibrated standards.

While auto-calibration is convenient, it's essential to note that even these systems need periodic checks against high-precision standards to ensure their reference values remain accurate. By maintaining calibrated tools, engineers and technicians can be confident in their readings, ensuring the integrity of their work and the safety of their projects.

Conclusion

From understanding the very fabric of digital instruments to appreciating the nuanced calibrations that ensure their precision, it's evident that these tools are more than just devices – they're the lifeline of modern electrical engineering.

They shape innovations, fuel discoveries, and bridge the gap between ideas and reality. But with rapid technological advancements, acquiring the latest instrumentation can be a costly endeavor.

At Keysight's Used Equipment Store, you'll find a vast selection of top-tier, carefully calibrated instruments at a fraction of their original price. Whether you're on the hunt for a state-of-the-art oscilloscope, a high-precision network analyzer, meter or any other piece of critical test equipment, explore Keysight's Used Equipment Store today and empower your projects with the best tools at unbeatable prices.

Browse Oscilloscopes at a Great Discount

Select up to 3 instruments to compare

Enable Notifications

In order to use this feature, you need to enable notifications.

Manage notification preferences

Whenever You’re Ready, Here Are 5 Ways We Can Help You

- Browse our Premium Used Oscilloscopes.

- Call tech support US: +1 800 829-4444

Press #, then 2. Hours: 7 am – 5 pm MT, Mon– Fri - Talk to our sales support team by clicking the icon (bottom right corner) on every offer page

- Create an account to get price alerts and access to exclusive waitlists.

- Talk to your account manager about your specific needs.