How to Check Signal Strength Of All Available Network Operators

Selecting the right DC power supply can feel like navigating a maze. Engineers often face a barrage of questions: Does the power supply provide enough current without compromising stability? Will noise levels interfere with sensitive measurements? And what about efficiency and heat management?

These are just a few of the challenges engineers encounter when powering up new projects or maintaining existing setups. The consequences of choosing the wrong power supply range from minor inefficiencies to equipment damage, making the decision even more critical.

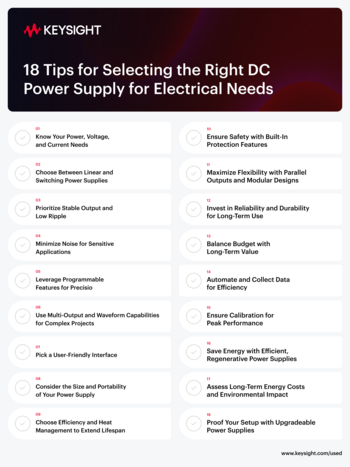

In this article, we provide 18 practical tips to help you select the right DC power supply for your electrical needs. Whether you're tackling a new design or optimizing an existing system, these insights will guide you in choosing the best power supply to ensure efficiency, reliability, and safety in your applications.

Understanding the specific power, voltage, and current requirements of your devices or systems is the foundation for choosing the right DC power supply. Every device, from simple sensors to complex testing equipment, has unique electrical needs.

If you underpower a device, it may not function correctly or could experience instability. Overpowering, on the other hand, could lead to overheating, damage, or even complete failure of sensitive components.

To avoid these pitfalls, calculate the minimum and maximum power, voltage, and current values your equipment requires. Start by checking the manufacturer's specifications for each device. Identify the nominal operating voltage and current, and then account for any variations under different load conditions.

It's essential to consider both the peak and continuous current requirements to ensure you select a power supply that can handle occasional surges without being oversized for its primary function.

Here are some common voltage and current requirements for various applications:

Getting these numbers wrong can lead to inefficiencies, such as increased power consumption or reduced device lifespan, and in some cases, severe equipment damage. Always double-check your calculations and choose a power supply that comfortably meets your device's needs to ensure optimal performance and longevity.

When selecting a DC power supply, one of the most critical decisions is choosing between a linear or switching power supply. Each type has its own advantages and drawbacks, depending on your project's requirements for noise, efficiency, and heat management.

Linear power supplies are known for their low noise and precise output, making them ideal for powering sensitive electronic devices, such as audio equipment, laboratory instruments, and medical devices where even minimal electrical noise can interfere with accurate measurements. However, they tend to be less efficient, as they dissipate excess energy as heat, which can lead to increased cooling requirements and a larger physical size.

Switching power supplies are highly efficient, converting power with minimal waste and generating less heat. This makes them a better choice for high-power applications, portable devices, and situations where space is limited. The trade-off is that they can produce higher noise levels due to their switching frequencies, which may interfere with sensitive electronics.

Here’s a quick guide on when to choose each type:

Below is a comparison table to help you decide which type of power supply suits your project needs:

| Aspect | Linear Power Supply | Switching Power Supply |

| Noise | Very low, ideal for sensitive devices | Higher, may interfere with sensitive devices |

| Efficiency | Lower (typically 40-60%) | Higher (typically 80-95%) |

| Size | Larger due to heat dissipation components | Smaller and more compact |

| Heat Generation | High, requires cooling | Lower, more efficient heat management |

| Cost | Generally more expensive due to components | Generally less expensive due to design |

By understanding these differences, you can select the power supply type that aligns best with your specific project requirements, ensuring you achieve both performance and efficiency.

Ripple refers to the small, unwanted residual periodic variation of the DC output voltage within a power supply, typically originating from the AC input signal. It appears as a fluctuating noise or wave that can interfere with the stable operation of electronic circuits. In sensitive electronics, even small ripples can cause inaccuracies, errors, or degraded performance, making a stable output essential.

A stable output with low ripple is crucial for applications that require high precision, such as test and measurement equipment, communication systems, and medical devices. Low ripple ensures that the voltage supplied to sensitive components remains constant and predictable, allowing these devices to perform consistently and accurately. When ripple is minimized, it reduces the likelihood of errors in data acquisition, signal processing, and overall device functionality.

To evaluate a power supply's stability and ripple characteristics, carefully examine the specifications provided in the datasheet. Look for key terms such as:

By prioritizing a power supply with low ripple and stable output, especially for high-precision applications, you ensure more reliable results, protect sensitive electronics, and maintain the accuracy and integrity of your systems.

Low noise levels are vital for applications involving sensitive electronics and RF (radio frequency) equipment. In these scenarios, even minor noise fluctuations from a power supply can disrupt accurate measurements, compromise signal integrity, or cause malfunctions in the circuitry.

For instance, in RF applications, noise from the power supply can mix with the signals being measured or transmitted, leading to distorted outputs and unreliable data.

Choosing a power supply with low noise becomes especially important in fields such as telecommunications, medical device testing, and high-frequency electronics. In these areas, the precision and clarity of signals are paramount, and any additional noise can directly affect the performance and reliability of the entire system.

When evaluating noise performance, look for the following specifications in a power supply's datasheet:

For applications such as telecommunications, where clear signal transmission is critical, or medical device testing, where patient safety and accurate diagnostics depend on stable power, selecting a low-noise power supply is non-negotiable.

Similarly, in high-frequency electronics like RF amplifiers or mixers, low-noise power supplies ensure that the device's output remains clear and consistent.

By understanding and assessing noise specifications, you can choose the right power supply that minimizes interference, preserves signal integrity, and ensures the highest level of accuracy and reliability in your sensitive applications.

Programmable power supplies provide precise control over voltage and current settings, which is essential in testing and automation environments where accuracy and repeatability are critical.

These supplies allow you to fine-tune power parameters down to the smallest increments, ensuring that your devices receive the exact amount of power needed, minimizing risks of damage or malfunction due to power fluctuations.

Benefits of Programmable Power Supplies:

Key Features to Look For:

By leveraging programmable features, you can optimize control, accuracy, and efficiency in your testing and development processes, making them an excellent choice for environments where reliability and precision are paramount.

Multi-output power supplies offer several advantages for projects that require different voltages or currents simultaneously:

Waveform capabilities allow you to create specific voltage or current profiles, such as ramps, pulses, or sine waves, which are essential for simulating real-world operating conditions or stress-testing components. This is particularly useful for:

Industries such as telecommunications, R&D, automotive, and aerospace can significantly benefit from multi-output and waveform capabilities, allowing them to handle complex projects more efficiently and accurately.

A clear, intuitive interface is essential for any power supply used in environments where frequent adjustments and monitoring are necessary. A user-friendly design minimizes the learning curve, allowing engineers and technicians to focus on their tasks rather than struggling with cumbersome controls.

Key features to look for in a user-friendly interface:

A well-designed interface not only reduces operational errors by preventing misinterpretation of settings or data but also enhances productivity by making it easier to configure and monitor the power supply. This efficiency translates into more accurate results, less downtime, and a smoother overall experience, ultimately leading to higher quality in testing and development processes.

The physical size of a power supply should align with your workspace and mobility needs. For portable applications, compact and lightweight designs are ideal, offering easy transport and convenience for fieldwork or on-the-go testing. These smaller units ensure you can carry out measurements and diagnostics wherever needed without being weighed down by bulky equipment.

However, for heavy-duty or lab-based setups that require higher power outputs, larger, more powerful stationary power supplies are necessary. These units provide robust performance and durability for continuous use, ensuring reliable power delivery for demanding applications.

Selecting the right size and portability ensures you have the flexibility and capacity needed for your specific projects.

Efficiency in a power supply directly affects energy consumption and heat generation. Higher efficiency means less energy is wasted as heat, reducing cooling requirements and prolonging the lifespan of both the power supply and the connected equipment.

Common Heat Management Systems:

Prioritize power supplies with high-efficiency ratings to minimize heat generation, especially in continuous-use or high-power environments, to extend the equipment's lifespan and reduce operational costs.

Built-in protection mechanisms are crucial for preventing damage to both the power supply and connected devices. Features like overvoltage, overcurrent, and short-circuit protection help safeguard equipment from unexpected electrical issues, reducing the risk of costly malfunctions.

Key Protection Features:

These safety features help maintain the longevity of both the power supply and the devices it powers, ensuring stable operation and reducing downtime.

Guidance for Verifying Safety Standards:

Ensuring that your power supply meets these safety standards and includes essential protection features can significantly minimize the risk of equipment failure and improve operational safety.

Parallel outputs can significantly increase total power capacity by allowing multiple outputs to be combined, providing higher power levels for projects that demand greater output.

This feature is particularly useful when a single power supply needs to support multiple high-power devices simultaneously or when the required power exceeds the capacity of a single output channel.

Modular designs offer the advantage of expandability, allowing you to scale the power supply system as project demands change. You can add or replace modules to meet new requirements, improving flexibility without needing to invest in entirely new equipment.

This adaptability is ideal for environments where needs frequently evolve, such as in R&D labs or production facilities.

Industries and Projects Requiring Flexibility:

Prioritizing power supplies with parallel output capabilities and modular designs ensures your setup can handle growing or changing demands efficiently, offering long-term value and adaptability.

Reliability is essential, especially in mission-critical applications where downtime can lead to significant costs or operational failures. In such environments, a dependable power supply is crucial to maintaining continuous operations and ensuring safety.

Durable construction and the use of high-quality components are key factors that contribute to the long-term usability of a power supply. These features help withstand demanding conditions, reduce the likelihood of failures, and extend the equipment's service life.

To ensure you select a reliable power supply, consider:

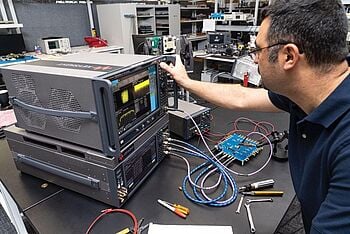

Keysight’s new and used equipment reflects our commitment to quality. All of our used power supplies undergo rigorous testing, calibration, and refurbishment to maintain high standards, ensuring you receive equipment that is both reliable and durable. This commitment to excellence makes Keysight a trusted choice for long-term use, even with pre-owned devices.

"Customers come to us and buy used, because they get premium KS quality, with a lower price and we ship within 2 weeks." – Keysight Account Manager

Balancing the initial cost of a power supply with its long-term value involves considering factors beyond just the purchase price. Durability, efficiency, and reduced maintenance all play crucial roles in determining the total cost of ownership.

A power supply with a higher upfront cost but superior build quality and energy efficiency can save you money over time by reducing repair costs and lowering energy consumption.

Used power supplies offer an excellent budget-friendly option, often providing the same level of performance and reliability as new units but at a reduced cost. High-quality refurbished equipment undergoes stringent refurbishment, testing and calibration, ensuring you don't compromise on quality.

When evaluating the best value, consider the total cost of ownership:

| Factor | New Power Supply | Used Power Supply |

| Initial Cost | Higher | Lower |

| Durability | Depends on brand and model | High, especially with refurbished equipment |

| Efficiency | Generally high, may include latest technology | High, especially in well-maintained units |

| Maintenance Costs | Lower, but depends on usage | May require more frequent checks but often minimal |

| Warranty Coverage | Typically longer | Often available (e.g., Keysight’s 1-year warranty) |

| Energy Savings | High, especially with modern efficient models | Comparable, depending on the model and condition |

By considering these factors, you can choose a power supply that aligns with your budget while maximizing long-term value, ensuring both performance and cost-efficiency for your projects.

Power supplies with automation features can greatly enhance efficiency in large-scale testing or industrial environments by:

Data collection capabilities offer additional benefits:

Look for power supplies that integrate well with data management software to streamline operations, simplify data analysis, and improve overall efficiency.

Regular calibration is essential to maintaining the accuracy and reliability of power supplies over time. Calibration ensures that the power supply delivers precise voltage and current levels, preventing performance degradation and reducing the risk of errors in critical applications.

Key points about calibration:

Check whether your power supply includes built-in calibration features for easy, on-site adjustments or if external services are required for ongoing maintenance.

Keysight’s premium used equipment is thoroughly calibrated to ensure peak performance and comes with the added benefit of a one-year warranty and post-purchase calibration service, providing peace of mind and long-term reliability.

Regenerative power supplies can feed unused energy back into the system, significantly reducing overall energy consumption. Instead of dissipating excess power as heat, these supplies return energy to the grid, improving efficiency and sustainability.

Cost-Saving and Environmental Benefits:

Recommended Industries:

Choosing regenerative power supplies is ideal for industries with high power demands, ensuring both economic and environmental benefits for long-term projects.

When choosing a power supply, it's important to consider its long-term energy consumption and environmental footprint. Evaluating the efficiency of a power supply helps you understand its impact on both your operational costs and the environment.

Key Considerations:

By carefully assessing these factors, you can make informed decisions that support both your budget and your commitment to sustainability.

Investing in upgradeable power supplies helps future-proof your setup by allowing for firmware updates and the addition of new features over time. This adaptability ensures your power supply remains compatible with evolving technologies and changing project requirements, saving you the cost and hassle of purchasing new equipment.

Benefits of Upgradeable Power Supplies:

Industries Where Future-Proofing is Critical:

By choosing upgradeable power supplies, you ensure your setup can keep pace with technological advancements and future project needs, providing lasting value and performance.

Choosing the right DC power supply can be challenging, but the right approach can make all the difference. By understanding your power needs, prioritizing stability, and leveraging the right features you can avoid common pitfalls that lead to inefficiencies or equipment damage.

Whether you're concerned about budget constraints, future-proofing your setup, or meeting sustainability goals, there’s a power supply solution that meets your needs.

At Keysight, we make reliable test results accessible and affordable. Our high-quality new and used power supplies offer precision, durability, and flexibility, ensuring you have the tools you need to power your innovations confidently.

Discover how our solutions can help you achieve your goals with unmatched performance and peace of mind.